Adamatic NDR System

Adamatic NDR System

Description

Adamatic NDR Roll line – overall dimensions: 40’4” L x 11’5” H x 47.5” W (Belt 32”)

Voltage: 220 / 3 ph

Included:

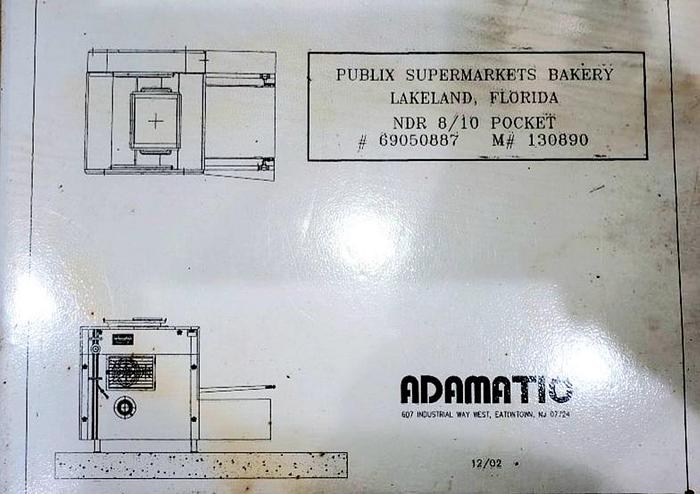

Glimek Chunker – Mounted above Adamatic NDR 8/10 Divider Rounder

Adamatic NDR 8/10 Divider Rounder

4 Pocket 5 - 10 oz, 6 Pocket 3 - 9 oz, 8 Pocket 1 - 7 oz, 10 Pocket 1 - 3 oz

Length 45 feet Width 7-1/2 Ft belt width 35 Inch

Capacity up to 24,000 pc per hr

No Divider Oil Required

2 Rounding Drums / 8 across

Several dividing block arrangements

Note: Additional dividing blocks and rounding drums available

Overhead Proover

Proofer 170 to 200 trays with an 8 to 10 minutes proof time

Heavy weight square tube design

Centralized Control Panel

Turret head roll stamper –

Stamped Kaisers, Split, Portuguese rolls.

A Slitter w proofer trays can be added for Portuguese rolls

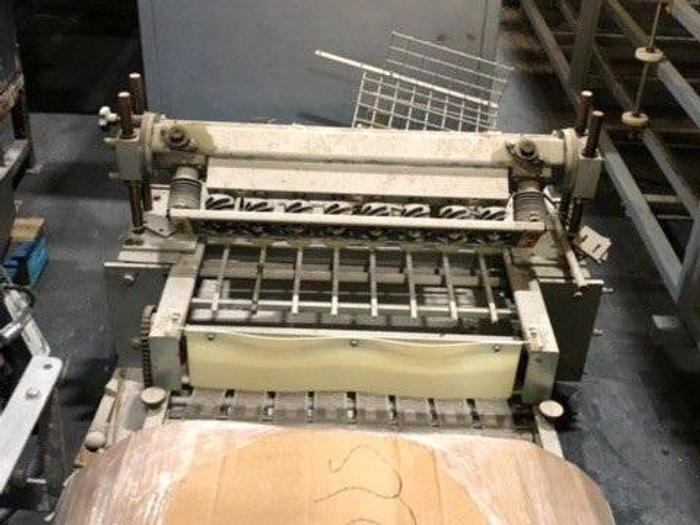

Sheeting Head

3 head design – fully adjustable

Moulds from 4” to 12” Hoagies

Moulding Station – 32” Usable Belt

Several Moulding Plates available

Reciprocating Panner with Row Control

Automatic Panning with cross conveyor

System to be fully rebuilt, Stainless-Steel exterior covers, NEW Conveyor belting, Updated Electrical package, Frame to be cleaned and repainted, NEW Bearings, chains and sprockets

Head Machine – each use a dividing block and piston (No Oil or Flour)

Rounding is done by dropping a dough ball into an outer drum that’s stationary and inner drum oscillates while compressing the dough piece to a belt.

All dough balls are rested in an overhead proofer.

All dough pieces are flatted out like a “Tortilla” through 3 sets of rollers.

All dough pieces are curled with a curling chain.

All dough pieces are moulded with adjustable pressure boards.

Specifications

| Manufacturer | Adamatic |

| Model | NDR |

| Year | 2002 |

| Condition | Refurbished |

| Voltage | 220 / 3 ph |